439 Stainless Steel Welding

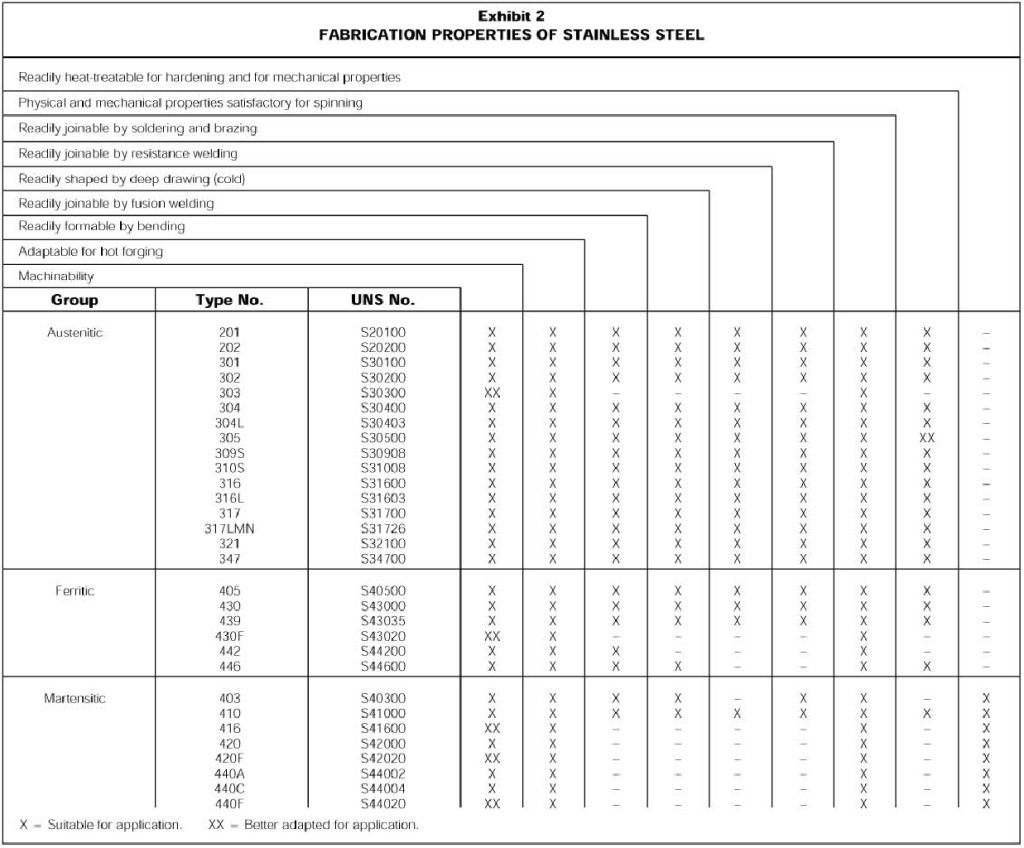

316l is an austenitic stainless steel and 439 is a ferritic stainless steel.

439 stainless steel welding. Ferritic stainless usually comes in thicknesses of in. This designation is related to the microstructure of the metal the differences can be seen under an electron microscope in this picture a is austenitic 304 and b is ferritic 430. Type 439 is a titanium stabilized 18 percent chromium alloy that may be used in many oxidizing environments where type 304 is considered adequate in terms of general corrosion resistance but is subject to chloride stress corrosion cracking. Welding duplex stainless steel.

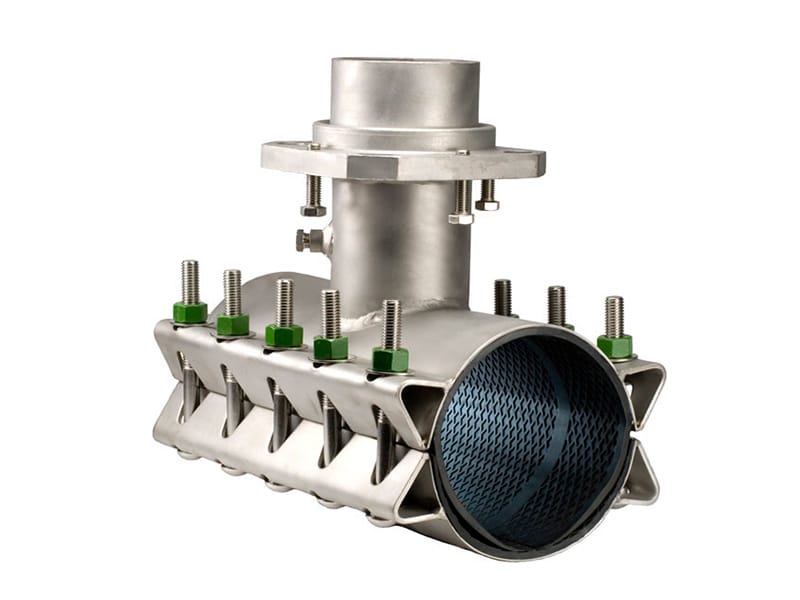

Type 439 stainless steel is a ferritic stainless steel designed to resist corrosion in a variety of oxidizing environments from fresh water to boiling acids. Or less so most welding with this material is done in a single pass. Duplex stainless steel is a combination of austenitic and ferritic stainless steel. Typically 409 or 439 filler material is used to weld ferritic stainless steels.

The two most common grades used in this application are 409 and 439. These two types of stainless steel are categorized by their microstructure. Titanium is the stabilizing agent utilized in this product. Ferritic stainless steel automotive applications use the most ferritic stainless steel.

It may be used in either the annealed cold formed or as welded condition in many applications where other stainless steel alloys such as type 304 type 410 type 409 and type 430are used. Select 439ti is a ferritic stainless steel composite metal cored electrode for gas metal arc or gas tungsten arc welding of 18 percent chromium steels used to fabricate exhaust systems. Description type 439 is an 18 chromium titanium stabilized ferritic stainless steel with corrosion resistance similar to that of 304 304l stainless steel. A ferritic stainless steel tube type 439 outperforms both type 409 and 436 in oxidation and corrosion resistance in the most demanding environments.

The composition of ati 439 stainless steel has been balanced to provide a completely ferritic structure at all temperatures to avoid the loss of ductility after welding and to provide resistance to intergranular corrosion. Preheating duplex stainless steel is usually not required. To weld stainless steel you should start at a high pulse rate of at least 100 pps and.